食微知註

Terranniki

Long time working on food safety aspect as well as the high school education, better understanding certain interesting stories worth for sharing with whom comes across here.

Food Microbiology?

微Microbiology is one of the categories in Biology. It is the study of microscopic organisms, such as bacteria, viruses, archaea, fungi and protozoa. This discipline includes fundamental researches on the biochemistry, physiology, cell biology, ecology, evolution and clinical aspects of microorganisms, including the host response to these agents.

Food microbiology is the study of the microorganisms of infectious agent, which inhibit, create, or contaminate food, which might affect the quality and safety of the food. We don’t provide further discussion in here as you can find out the relevant information from your textbook or internet. Yet, we suggest bringing your attention to an infectious agent – prions, a pathogenic factor that we seldom pay attention to but it is a highly infected issue in food microbiology.

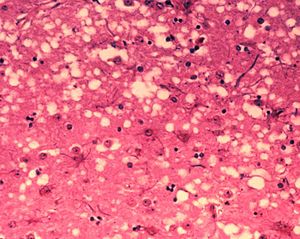

Prion

Prions are misfolded proteins with the ability to transmit their misfolded shape onto normal variants of the same protein. Prion isoforms of the prion protein (PrP), whose specific function is uncertain, are hypothesized as the cause of transmissible spongiform encephalopathies (TSEs), including scrapie in sheep, chronic wasting disease (CWD) in deer, bovine spongiform encephalopathy (BSE) in cattle (commonly known as “mad cow disease”) and Creutzfeldt–Jakob disease (CJD) in humans. All known prion diseases in mammals affect the structure of the brain or other neural tissue; all are progressive, have no known effective treatment and are always fatal. Therefore, to prevent infectious agent from entering to the food chain, severe inspection before the slaughtering process is very important (even though we could not guarantee).

Never purchase meat from unknown source.。

That is the reason why!

Virus

The virus is mostly found in the contaminated food or water or person-to-person contact or unsanitary food preparation process among retail outlets and suppliers. In the United States, Norovirus is identified as the cause of about half of all foodborne disease outbreaks. Norovirus is a most common cause of a gastroenteritis infection, which is a highly infectious agent after an unsanitary food preparation or contaminated raw or unfinished shellfish. Moreover, hepatitis A, hepatitis E and rotavirus are also the other common viral diseases found and spread through contaminated food among retail outlets and suppliers.

Precise supervision to maintain the health of catering staff is very essential.

That is the reason why!

Microorganism and food spoilage

Meat

During the food processing after slaughtering, meat and poultry undergo deterioration to varying degrees into three organoleptic spoilages. 1) Autolytic spoilage caused by enzymes. It is stated that autolytic enzymes reduced textural quality during early stages of deterioration by degrading the product quality but did not produce the characteristic spoilage off-odors and off-flavors. 2) Fat or Lipid oxidation. During the Lipid oxidation process, various complex set of oxidative degradation of lipids are formed, depending upon the types of fatty acids and the oxygen availability. 3) Microbiological spoilage caused by bacteria. It could exist in those raw meats even after food processing. Meat deterioration or spoilage is often the final result unless effective inhibition or elimination is carried immediately.

There are two general properties that microorganism could cause food deterioration or spoilage. 1) With the presence of microorganisms. Food deteriorates when the bacteria and metabolism are operating simultaneously within an environment. 2) Without the presence of microorganisms. Food deteriorates when decomposition reacts the bioactive compounds of the food, which changes the chemical activities in natural food enzymes.

Proper measures should be taken immediately for every purchased food.

That is the reason why!

To whom should take extra attention upon food safety; to avoid food poisoning

- Age 65 or above 65

- When comparing with the other ages’ groups, elderly are apparently the highest risk in encounter food poisoning. They could not identify and eliminate the bacteria which attack their bodies due to the degeneration of immune system along with the growing ages. According to the confirmed laboratory statistic, hospitalization rate at age 65 or over are 50% higher than the others when they come across with the bacteria of Salmonella, Campylobacter, Listeria or Escherichia Coli….

- Age 5 or under

- The ability in resisting various bacteria is not strong enough for a child as the immune system is still developing. Food poison to a child could be fatal as the bacteria would cause diarrhea and dehydration. According to the CDC statistic of the United States, the probability of a kid at age 5 or under who is suffering from Salmonella is 3 times more than the other ages’ groups. For instance, for every 7 child at age 5 or under, 1 would be diagnosed with Escherichia Coli “O157”, resulting in kidney failure.

- Immune system inferior group

- The immune system of these people could not resist the attack of the bacteria because they are suffering from diabetes, liver or kidney disease, alcoholism, AIDs; or currently under the treatment of radiation therapy or chemotherapy. The probability of a dialysis patient who gets infection from Listeria is 50 times higher than the others.

- Pregnant women

- Pregnant women are easier being infected with bacteria. For example, the probability of a pregnant woman who gets infection from Listeria during pregnancy is 10 times higher than the others.

Terranniki is devoting himself in every aspect of research and development to safeguard the health of the family and friends.

The reason why?

Q&A

Q1- Why the products of Terranniki could endure for a very long time without the preservatives?

Hygiene

We have applied several measures in determine a hygienic environment of the workshop such as the floor, the facilities and the sanitary factors to make sure the outputs are healthy and reliable.

Freeze-Dried

Vacuum freeze-dried method minimizes the growth of microorganism in term of water lackage. The glucose content because of concentration and low water activity (Aw) level could effectively control the growth of any microorganism in terranniki’s products.

Vacuum packing

Vacuum packing by minimizing the air within the bag is the best way to extend the shelf time of the products because it prevents the oxidization and harmful microorganism from growing. Attention on Clostridium botulinum and Listeria monocytogenes has always been taken so that we emphasize the importance of pretreatment of sterilization.

Q2-

Why Terranniki use hot water and ultrasound treatment in purifying and finishing the veggies?

Ultrasound

Ultrasound is not only used in tracing tumors or pregnancy checking, kidney stone removal, it can also be used in food processing area such as extracting cellular material. By using ultrasound, tenderization and oxidation of meat has improved the food nature.

Low frequency (20–100 kHz)

At present, low-frequency ultrasonic purifiers are used, which mainly use the mechanical effects caused by unstable cavitation. The bubbles collapse with the drastic changes in the surface pressure of the cells/microbes after repeated blasting, which is beneficial to the subsequent overflow of water vapor and the reduction of bacteria. Accompanying Basque disinfection can increase efficiency and shorten time.

Q3-

Why do we prefer to store finished products in glass bottles instead of light and convenient vacuum bags?

Glass bottle

It cannot be denied that the use of high-quality glass bottles and the additional ball cap (Ring&Lid) for vacuum package greatly increases the cost, and takes up a lot of storage space and is not friendly carrying. We still insist on it because it is stable, highly reliable, environmentally friendly and can be used repeatedly (glass bottles), can be sterilized at high temperature and does not worry about plasticizers or other chemical residues such as ENMs. (Namely Nano-materials, which have been widely applied on packaging in recent years).

Q4- Why do we choose Ozone as the only purification agent?

Ozone is a strong oxidant and has been approved for application in many fields. Ozone is used in food processing and disinfection, and even in the medical field, ozone is used for disease treatment, as long as there is no negative news ever since.

We adopted it as the only purification tool on a basis of the ability of ozone to instantly decompose organic matter, bacteria and microorganisms in the water. After the purification process, it will only be decomposed into oxygen and dissolved in the water, without producing any other residues or pollution, which In line with Terranniki’s pursuit and philosophy.

Q5- Why we choose Mason jar as storage container?

The glass jar can be used repeatedly. It is transparent and can always be observed for changes or irregularities in the storage. It can be put in a disinfection cabinet for high temperature disinfection before use.

Mason jars, also known as glass sealed jars, are divided into standard and wide-mouth glass calibers. They were invented as early as 1858 and are still widely in use today. Their reliability has been affirmed in practice. They are widely used in the West for glass canned foods in households. The can mouth has threads on its periphery to receive a metal lid. When locked, the metal cap presses on the rim of the can. The integral rubber ring on the underside of the cover forms an airtight seal. Although these lids are theoretically reusable, they are usually only used once or twice during canning. The packaging machine helps to generate a vacuum in the top space of the can. Pull the lid to closely contact the edge of the can to form a concave dome. Improper sealing or failure or microbial growth will cause the dome to pop up.

Q6- Why we use Escherichia Coli and Salmonella as QC test indicators?

So far, the main pathogens associated with low-moisture foods (Aw<<0.85) include Salmonella and Bacillus cereus. However, most of the outbreak-related diseases associated with low-moisture foods are caused by Salmonella. Therefore, Codex Alimentarius Code of Hygienic Practice initiative focuses on the control of Salmonellae. Investigation and research have found that the fundamental safety of low-moisture foods depends on the control of Salmonella in the food handling environment. Escherichia coli is commonly used as an indicator of environmental monitoring, so the studio commissioned a third party to conduct random inspections for bacterial testing with two indicators: Escherichia coli and Salmonella.

Q7- My wife asks me why I prefer not to use meat and dairy products from USA as the ingredients?

As far as we know, according to the public information, most of the livestock animals before slaughter in the United States (for example, pigs account for about 60-80%) will be legally fed by Clenbuterol-Ractopamine. The purpose is to increase the synthesis of muscle protein, increase the size of muscle fibers, increase weight, and improve feed efficiency and increase the body weight. Research institutes have found that Ractopamine can cause severe disability in animals, including shaking, broken limbs and inability to walk. Since 1996, Ractopamine has been banned by most international countries such as the European Union, China, and Russia. The United States insists on using it based on the fact that it can make greater profits (for example, each pig adds about three kilograms of lean pork, and the feed efficiency increases by 10%). Under the huge shadow of the chaebol of interest, the US Food and Drug Administration (FDA) states that the safety within the safe residue has passed the scientific inspection (data provided by the manufacturer), so it is allowed to continue to be used in feed, and only requires no "Use directly "on the human body. In addition to the United States, countries around the world that approved the addition of Ractopamine to cattle feed include Canada, Mexico, and Indonesia. Taiwan Province approved the use in 2012. Brazil is one of the main sources of supply to the US market and it has advantages. Although it is not clearly stated, it can be reasonably inferred that there are Brazilian meat products. A similar situation also occurs when steroid hormone drugs are used in beef production.

Ractopamine

Cheap and Yummy, what’s the trick?

Q8- Some Western countries have concerns about the “safety” of steroids and hormones in cattle breeding!

The US Food and Drug Administration (FDA) allows many steroids and hormone drugs to be used in beef and dairy production. Farmers are driven to use hormones because they enable animals to grow up faster with less feed or to produce more meat, thereby reducing production costs. Since 1989, the European Union has banned the sale of hormone-treated beef. The 2003 EU scientific review concluded that estradiol – 17β (estradiol – 17β) has a carcinogenic risk (such as breast cancer), and there is insufficient data to fully assess the health hazards of the other five common beef hormones; In view of safety concerns, the European Union amended its decree to temporarily ban the five beef hormones and permanently prohibit estradiol-17β from being used on cattle. This decision led the United States to oppose the EU’s decision to the World Trade Organization (WTO) in 1998.

Cattle popular steroids and hormone drugs

rBGH- milk production(BST)

estradiol

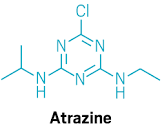

Q9- The safety facts of Atrazine have been “sealed” by profit!

It is estimated that Atrazine is the second most used herbicide in the United States, using 73.7 million pounds in 2013. It is used in more than half of all corn crops and up to 90% of sugar cane fields. Atrazine is also one of the most widely used herbicides in Australian agriculture. It is estimated that its impact on corn yield is 1-8%, and another economic review concluded that it is 3-4%. In another study, analyzing comprehensive data from 236 university studies on corn fields from 1986 to 2005, the use of Atrazine can yield an average increase of 5.7 bushels per acre compared with other herbicides. It is estimated that the impact on sorghum yield is increased by 20%. The strong benefits and lack of alternatives that can be used in sorghum fields are the incentives for Atrazine to be pursued. Atrazine was introduced to China in the 1980s and is widely used in large farmlands across the country. According to reports, China’s agricultural production of Atrazine reached 2,800 tons in 2000, an average annual growth rate of 20%.

Atrazine,ATR

However, Atrazine is also a highly effective endocrine disruptor, which can reduce the immune function of wild animals, plants and laboratory rodents. The chemical residue is also believed to induce breast and prostate cancer. If pregnant women absorb Atrazine in drinking water, it is related to fetal weight loss and heart, urinary and limb defects. Experimental animals have also been shown to slow down the development of fetuses in animals. Exposure to high levels of Atrazine can even lead to premature delivery of the fetus. Despite these findings, the US Environmental Protection Agency (EPA) still allows it to be used in large quantities in American agriculture. Due to its public health risks and its impact on water pollution, the European Union has banned its use in 2003. In 2016, the United States still only promoted the phase of community suspension.

Q10- Why I need to stall one more Sino-Freeze dryer other than those three US-HarvestRight freeze dryers!

US-Harvest Right is the home edition and is designed for home DIY. It’s smart program controls all the matters and one only needs to switch on/off the machine and to clean afterwards. However, it’s drying program is fully automatic and can not adjust except the time duration. Heating Cycle is based on the pressure sensor so that there is no way to set the drying recipe in term of different materials. For the sino-machine, everything is adjustable so as to be able to set specific recipes for floral and sea food and to get better final outlook.

You must be logged in to post a comment.